Electrostatic discharge (ESD) can silently destroy your electronics. Learn simple, proven ESD protection methods to stop static damage, protect your components, and stay compliant with safety standards.

Have you ever touched your PC and felt a tiny zap? That’s electrostatic discharge — and it’s not just annoying. ESD can ruin sensitive electronics in a second. I once fried a $300 graphics card just by handling it in my living room without a wrist strap. Most people don’t even realize they’re at risk until it’s too late.

If you’re working with electronics—whether in a repair shop, assembly line, or home lab—you need to know how to prevent ESD damage. But the good news is, the right ESD protection methods are easy to use, affordable, and often just small habits or tools away. In this guide, I’ll walk you through the most reliable ways to stay safe from static—step by step. You’ll also see real-world examples, product insights, and common mistakes to avoid.

What Is Electrostatic Discharge (ESD) and Why It Matters

Electrostatic discharge, or ESD, happens when static electricity jumps between objects. It can silently destroy electronics, making protection methods crucial in electronics handling and repair.

Understanding the Science of ESD

Electrostatic discharge (ESD) occurs when two objects with different electrical charges touch or come close. This can cause a sudden flow of electricity—too small to feel, but enough to damage a microchip. Most ESD events happen when humans touch devices without grounding themselves first.

Voltage range and discharge damage

Even low voltages can cause major problems. Just 100 volts can harm a sensitive microchip. The shock you feel from a doorknob? That’s over 3,000 volts. But ESD that kills electronics often goes unnoticed.

Human Body Model (HBM) vs Machine Model (MM)

In ESD testing, the Human Body Model (HBM) simulates discharge from a person—usually 1000 to 1500 volts. The Machine Model (MM) mimics a charge from a machine or metal tool. MM typically delivers higher current over a shorter time, making it even more destructive.

If you’re in electronics design, manufacturing, or repair, you need to understand both. They’re standard in ESD compliance testing across industries.

Common ESD Failures in Real Life

You don’t need a lab to see the damage ESD can cause.

A Reddit user shared a painful lesson: they destroyed their $250 gaming motherboard just by touching it while building a PC—without wearing an anti-static wrist strap.

It’s more common than you think. According to the EOS/ESD Association, ESD causes over $5 billion in damage each year across electronics industries worldwide.

You may never notice ESD damage at first. But later, your device might glitch, freeze, or stop working entirely—leaving you wondering why.

Important!

- ESD can happen at voltages far below what humans can feel

- Most everyday electronics lack built-in ESD protection

- One small mistake—no wrist strap, dry air, metal tool—can destroy critical components

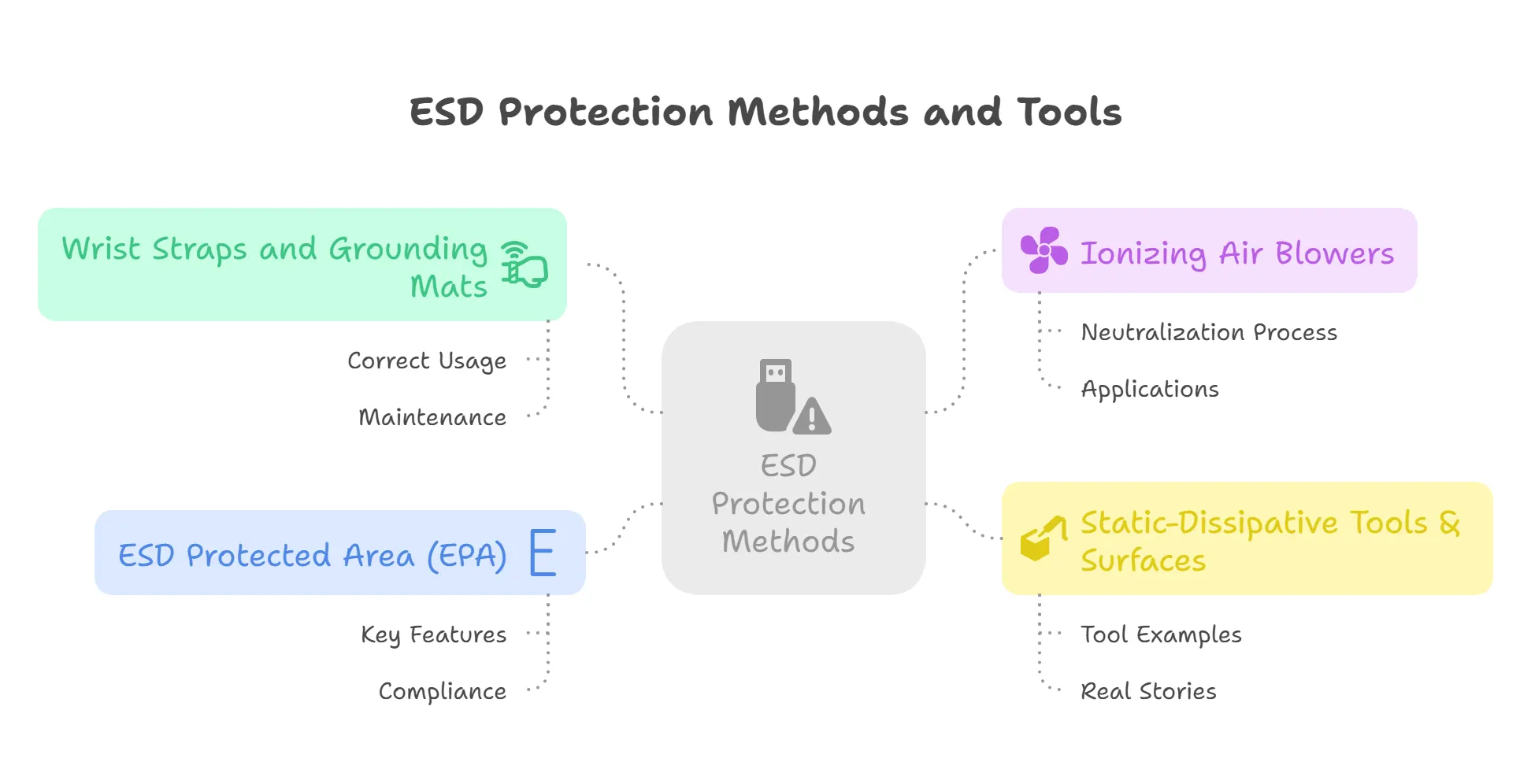

Core ESD Protection Methods That Actually Work

To stop ESD damage, use tools like wrist straps, grounding mats, ionizers, and static-safe gear. These methods protect electronics during handling, repair, and assembly.

Wrist Straps and Grounding Mats

How they work + correct usage

Wrist straps connect your body to ground through a resistor. This keeps static from building up on your skin. Grounding mats do the same for your workbench.

To use them right:

- Wear the strap snugly on bare skin

- Clip it to a grounded metal part (like a case or mat)

- Always test for continuity using an ESD checker

A verified buyer on Amazon said:

“This $10 wrist strap saved me from frying multiple builds. Cheap peace of mind.”

Frustration warning:

Another user noted their grounding mat stopped working until they tested and reconnected it properly.

Don’t just buy these tools—maintain and test them regularly.

Ionizing Air Blowers

How ionizers neutralize static charges

Ionizing blowers release a balanced flow of positive and negative ions. These ions neutralize static on objects or in the air—especially useful in dry rooms where charges build easily.

In electronics labs or cleanrooms, ionizers help protect circuit boards and sensitive parts that can’t be grounded directly.

Review insight:

A YouTube user commented:

“Was skeptical at first, but in our cleanroom, this thing eliminated so many micro defects. Total game-changer.”

Ionizers are a must when working with plastic parts, open PCBs, or in low-humidity areas.

Static-Dissipative Tools & Surfaces

ESD-safe screwdrivers, tweezers, table mats

Regular tools can store and discharge static. ESD-safe tools are made with static-dissipative or conductive materials to safely bleed off charge.

Examples:

- Tweezers with conductive plastic coating

- Screwdrivers with grounded handles

- Work surfaces with dissipative mats and grounded cords

Real story from Quora:

One technician shared how a metal screwdriver fried a $400 circuit board during diagnostics. Switched to ESD-safe tools after that.

Amazon review quote:

“Felt like overkill… until it saved a prototype from shorting out. Worth every penny.”

Even if you’re just repairing a phone, don’t skimp on safe tools.

Creating an ESD Protected Area (EPA)

An ESD Protected Area (EPA) is a designated space where all items, tools, and people are controlled to avoid ESD damage.

Key features:

- Grounded tables and flooring

- Static-dissipative chairs, shelves, and tools

- Humidity control (above 40% RH reduces ESD risks)

- Entry signs and access control

Compliance tip:

Follow the ANSI/ESD S20.20 standard. It defines best practices for protecting sensitive electronic components from ESD.

Checklist for small labs:

| EPA Element | Must-Have Items | Notes |

|---|---|---|

| Workbench | ESD mat, grounding cord | Test daily |

| Tools | ESD-safe tweezers, screwdrivers | Store in static-safe pouches |

| Personnel grounding | Wrist straps, heel straps | Use continuity testers regularly |

| Signage | “ESD Protected Area” signs | Prevents untrained access |

| Environmental controls | Humidifier, anti-static flooring | Monitor RH with hygrometer |

Even small workstations can be upgraded to meet EPA standards affordably.

ESD Protection Devices for Workstations & Circuits

What are the best ESD protection devices? Use ESD wrist straps, grounding mats, and TVS diodes to protect electronics from static discharge during repair or manufacturing.

Electrostatic Discharge (ESD) protection devices are crucial in both workstation and circuit-level safety. These tools absorb or redirect static charges before they reach sensitive electronic parts. The right combination of grounding, shielding, and suppression can prevent costly failures and ensure long-term reliability.

TVS Diodes and Suppression Components

What is a TVS diode and how does it protect circuits? A TVS diode stops voltage spikes from damaging a PCB by absorbing excess energy instantly.

Transient Voltage Suppression (TVS) diodes are placed across circuit inputs and outputs to clamp high-voltage spikes caused by ESD. These are especially common on USB, HDMI, and power rails in PCBs. They’re fast, reliable, and often invisible to end users—but absolutely vital for circuit protection.

🔧 Where They’re Used: You’ll find TVS diodes on data lines, power inputs, and microcontroller pins. They protect expensive ICs by instantly conducting excess voltage to ground.

💬 Expert Quote: One engineer on a Reddit AMA said, “I won’t ship any consumer electronics without TVS diodes on exposed ports. It’s cheap insurance.”

📌 Diagram Suggestion: A labeled PCB showing exposed input lines, TVS diode placements near USB ports, and ground routing to a suppression layer.

Grounding Plug Adapters and Monitors

Do grounding adapters actually work? Grounding adapters can protect electronics, but only if your wall outlet is truly grounded. Use a tester to check first.

Grounding plug adapters and continuous monitors ensure your workstation stays at the same electrical potential as the ground. This reduces the risk of charge buildup on tools and bodies. For commercial settings, continuous monitors are preferred. For home repairs, grounded plug strips and mats can help.

📢 Amazon Review Highlight: One buyer wrote, “I bought a grounding adapter, but my tester showed no ground! I could have fried my whole board!”

📊 Visual Tip: Include a table comparing grounding options:

| Product Type | Best For | Price Range | Notes |

|---|---|---|---|

| Grounding Plug Adapter | Home workbenches | $5–$15 | Needs a verified grounded wall |

| ESD Monitor | Commercial labs | $50–$150 | Alerts if ground is broken |

| Grounding Wrist Strap | All users | $5–$25 | Must connect to ground point |

Following ESD Protection Standards (And Why They Matter)

What is the ESD protection standard? The most used ESD protection standard is ANSI/ESD S20.20. It tells companies how to keep electronics safe from static.

Standards matter because ESD damage isn’t always visible immediately. The ANSI/ESD S20.20 standard outlines clear steps for minimizing risk across workplaces, from grounding rules to material usage. Whether you’re an engineer or a business owner, following these standards can reduce failures and protect profits.

Overview of ANSI/ESD S20.20

What is ANSI/ESD S20.20? ANSI/ESD S20.20 is a standard that tells companies how to prevent static damage in electronics manufacturing and repair.

The ANSI/ESD S20.20 standard is widely recognized in electronics manufacturing and required by many clients and auditors. It details protection methods, audit protocols, and compliance rules. You can download the standard PDF here via ESDA.org.

How to Pass an ESD Audit

How do I pass an ESD audit? To pass, make sure all employees use ESD-safe gear, follow grounding rules, and keep audit logs.

To pass an ESD audit, use a checklist that includes verified wrist straps, grounded mats, anti-static clothing, and written procedures. Also check your grounding points, material certifications, and employee training.

📉 Story: A Facebook post from a small tech repair business shared, “We failed our first ESD audit because the techs wore regular sneakers instead of certified shoes. We had to replace everything to get certified.”

Building a Company-Wide ESD Control Program

How do I create an ESD control program? Start with weekly tests, staff training, and ESD-compliant tools. Use sign-off sheets to track it all.

A full ESD control program includes weekly wrist strap testing, signed equipment checklists, and mandatory staff training. Visual posters, mat check logs, and EPA (ESD Protected Area) labels help keep everyone compliant.

📈 Data Point: According to IPC, companies with a full ESD program reduce electronic component failure rates by over 60%.

Important!

- Always test grounding equipment weekly.

- Use the ANSI/ESD S20.20 checklist.

- Train every new employee within their first week.

Real-World Results: What Users Say

Do ESD protection methods really work? Yes! Many users report saving expensive electronics by using grounding straps and ESD-safe tools.

The best proof of ESD protection is in the real-world stories shared by professionals, hobbyists, and manufacturers. Let’s look at a few examples.

Reddit Case 1: Preventing Laptop Board Burnout

Can ESD damage laptops? Yes. But using ESD protection like grounding mats can stop static from ruining motherboards.

A Reddit user shared how their $900 gaming laptop motherboard survived a full tear-down because they used a grounding mat and wrist strap. “I used to think it was overkill, but after reading about microcracks caused by static, I never skip it now.”

Amazon Review: Frustrations With Cheap Straps

Are cheap ESD straps worth it? No. Cheap straps often break. Spend a little more to get reliable ESD protection.

One verified Amazon reviewer wrote, “The clip snapped on day 2. Spend the extra $5 and get a real ESD wrist strap. Don’t risk your motherboard to save a coffee.”

Quora: How a Compliance Officer Used EPA to Cut Failures

What is an EPA in ESD safety? An EPA is a workspace set up to prevent static. It includes grounded mats, wrist straps, and warning signs.

A Quora contributor, an ESD compliance officer, said, “We created a small ESD Protected Area (EPA) in our service bay. One audit later, failure rates dropped to nearly zero.”

Common Mistakes That Ruin ESD Safety

What are the most common mistakes that can ruin ESD protection?

Many technicians make simple mistakes—like wearing the wrong clothes or forgetting to test tools—that can break ESD protection without realizing it.

Even with the best ESD tools, small oversights can lead to serious damage. Here are common errors that quietly sabotage your static safety plan:

Wearing nylon or synthetic clothes

Synthetic fabrics like nylon and polyester build static as you move. When you lean over a PCB, that charge can jump—damaging components instantly. Always wear 100% cotton or anti-static lab coats. Avoid fleece, yoga pants, and synthetic jackets.

Quote from user on Reddit:

“I zapped a $120 GPU just by leaning over it in a hoodie. Didn’t even feel it. Never again.”

Using USB-connected wrist straps

USB wrist straps are popular—but risky. Many offer no true ground connection. If your PC isn’t grounded, neither are you. Stick with professional wrist straps that plug into a grounded jack or mat clip.

Grounding wrist but not mat

Grounding yourself is smart. But forgetting to ground your mat means sensitive parts still sit on a charged surface. Both must be grounded to the same point using a common ground cord.

Pro Tip: Use a 10mm stud-to-banana plug cord to connect your mat and strap to a shared ground.

Forgetting daily resistance tests

Resistance-to-ground (RTG) checks are vital. Skipping them allows unnoticed failures in cords, mats, or wrist straps. Set a reminder and log the results to meet ANSI/ESD S20.20 compliance.

Real comment from Facebook electronics group

“My cousin lost his entire repair income last month. A client’s MacBook Pro got fried because he trusted his mat was grounded—it wasn’t. Turns out the cord broke inside the clip.”

— From ESD Safety & Repair Professionals Group (FB)

Don’t let small mistakes destroy high-value gear. Check clothing, test grounds daily, and never trust USB wrist straps.

Final Thoughts: Smart Static Control Starts with Small Habits

What’s the best way to stay protected from ESD long-term?

Make ESD safety a habit. Test your gear, follow grounding steps, and always work in a controlled static-safe space.

Big protection starts with small habits. That’s the golden rule of electrostatic discharge safety. Whether you’re repairing phones or assembling motherboards, consistent attention to detail is what keeps your workspace safe.

- Wear the right clothing—always anti-static.

- Ground both your body and surface before touching components.

- Check your tools daily, especially wrist straps and mats.

- Log RTG tests and follow EPA guidelines.

Build Your Own ESD-Proof Workspace

You don’t need a huge budget to get started. Here are affordable tools you can try now:

| Tool | Purpose | Best For |

|---|---|---|

| ESD Wrist Strap | Discharges static from body | All repairs |

| ESD Grounding Mat | Static-safe work surface | Benchtop electronics |

| RTG Tester | Measures resistance-to-ground | Daily compliance checks |

| Ionizing Air Blower | Neutralizes static in air | Precision work |

| ESD Shielding Bags | Stores sensitive parts safely | ICs, RAM, GPUs |

Start with a wrist strap and mat combo. Later, add a compliance tester like the ACL 750 for accurate monitoring.

“Every time I skip grounding, I get paranoid. One static shock can cost me hours of work.”

— ESD repair tech on YouTube comment thread

Small, daily habits like testing tools and grounding gear are what prevent costly failures. Start today—even basic tools make a difference.

I’m a tech enthusiast, entrepreneur, digital marketer and professional blogger equipped with skills in Digital Marketing, SEO, SEM, SMM, and lead generation. My objective is to simplify technology for you through detailed guides and reviews. I discovered WordPress while setting up my first business site and instantly became enamored. When not crafting websites, making content, or helping clients enhance their online ventures, I usually take care of my health and spend time with family, and explore the world. Connect with me on Facebook, Twitter, Linkedin or read my complete biography.